- Home

- Case Studies

- Lean Amine Filtration in a Natural Gas Processing Plant

Raw natural gas usually contains various contaminants which mainly consist of acid gases (CO2, H2S, etc.), water, other gases (nitrogen, helium) and mercury. In this particular process, raw gas was first fed into a three-phase separator, where gas was separated into sour gas, condensate, and water condensate respectively. After proper filtration treatment, the condensate was then sent to a condensate stabilization plant and then was fractionated into sales LPG/gasoline. The water was purified with proper treatments in a water treatment plant, meanwhile, sent to a stripper to recover hydrocarbon carried over.

Sour gas first flows through an amine absorber where CO2, H2S are removed by lean amine. Rich amine then flows into a regeneration column, where acid gases are released into a claus unit and the lean amine is regenerated and recycled. Following the amine absorber, there is a dehydration unit where sweet gas is dehydrated by using MEG. Dry gas is then sent through a chiller to a fractionation column where condensates are sent to fractionation plant, and sales gas will be transferred through transmission plant. Meanwhile, rich MEG needs to be regenerated by a stripping column. However, rich MEG contains traces amount of rust, dust and solid particles and must be removed prior to the Stripper column, otherwise, it will cause corrosion of re-boiler.

After evaluating this process and reviewing the spec sheet provided by the client, Pentair recommended and provided a particle separator; ProcessOR and an AdsorbOR which were sized to fit the application. As indicated in the process flow diagram on the PDF version, a pre-filter with 25um rating is applied to remove large particles to protect Activated Carbon bed (AC bed), which is for removing color and odors in lean amine. A 10 um rating PrecessOR is positioned after the AC bed to remove active carbon powder carried over if any.

DOWNLOADS

| Title | Download PDF |

| Lean Amine Filtration in A Natural Gas Processing Plant | Download |

Related technologies

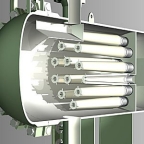

The ProcessOR is a superior separator vessel often used for particle/liquid filtration or separation. It is available to be delivered as a self-contained skid (pictured) or a stand-alone vessel. It is also available custom sized as a capital sale or as a turn-key rental, which is often available within days of the received order.

UltiSep technology was developed to address the inherent deficiencies of the conventional gas-liquid separators, making it possible to effectively remove liquid aerosols from gas streams. UltiSep

LiquiSep technology has been implemented specifically to help separate emulsions that are not separable by conventional coalescers. Conventional coalescers are unable to provide the degree clarity associated with LiquiSep technology due to the inability to capture and remove the most penetrating droplets that cause carry-over. LiquiSep can separate these dispersed and emulsified droplets from the hydrocarbon to practically non-detectable levels.